When it comes to productivity and efficiency in converting and label production, every little bit counts. While it may seem insignificant, even a small increase in speed can have a substantial impact on overall production output. This was something that was brought to my attention while on site with one of my existing customers as we were discussing the performance of their PAC Trim & Waste systems.

We were conducting some maintenance and service for a future expansion, and during this time were required to take the PAC system offline. This gave us the opportunity to observe and record the speed differential between the two processes on one specific press. As it turns out, when the PAC system was down, and the press operator manually wound the matrix, the speed was 400 feet per minute in comparison to the 450 feet per minute when the PAC system was active and running. This difference of 50 feet per minute got me thinking about the potential impact of such a small variance.

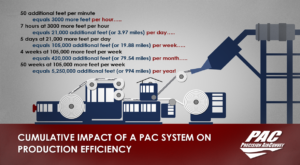

To put it into perspective, if a press achieves 50 more feet of material in one minute and runs for 60 continuous minutes, that equates to an additional 3000 feet processed in one hour. While that may not seem like a lot, when you take into consideration that the press is running for 7 hours a day, that extra 3000 feet per hour quickly adds up to 21,000 feet, or 3.97 miles of additional produced material daily. Therefore, assuming a 5-day work week, this adds 105,000 additional feet or 19.88 miles of additional product per week. And when you extrapolate that to 4 weeks of production, that number jumps to an additional 420,000 feet or 79.54 miles per month.

If the press is able to maintain this increase of 50 feet per minute for an entire year, working 5 days a week, 7 hours a day, the total amount of additional material processed would be 5,250,000 feet or 994 MILES! And, bear in mind, this additional production is for just ONE PRESS!

These calculations highlight the importance of constantly analyzing and looking for ways to improve productivity in any operation. Inefficiency can lead to significant financial opportunity losses, and it’s important to consider even the smallest of changes can make a big impact.

BW 2023