PAC OIL: The #1 choice for PSA oil mist injection systems

PAC OIL, a proprietary oil blend, is the ideal lubricant for the Precision AirConvey (PAC) EnviroPulse Oil Misting system. PAC OIL is formulated to keep your EnviroPulse system in top shape, ensuring your system’s longevity and continuous high-level performance.

PAC’s exact sourcing and blending standards mean the first drop of PAC OIL is the same as the last. PAC OIL can also be used with any manufacturer’s oil mist injection system. Using PAC OIL saves you time and money.

SDS Available Here

Available in:

- 5 Gallon Buckets (24 on a skid)

- 55 Gallon Drums (4 on a skid)

- 275 and 330 Gallon Recyclable Totes — Recyclable totes are a one-way shipment. To recycle totes, call the National

- Container recycling number on the tote

- 275 and 330 Gallon Disposable Totes

Keep Your Production Line Running Smoothly with enviropulse

Stop blockages and delays caused by PSA materials. EnviroPulse is the efficient and economical way to prevent trim and matrix materials from sticking.

Don’t let stray PSA trim bring your system to a standstill. EnviroPulse keeps your shop operating at maximum efficiency.

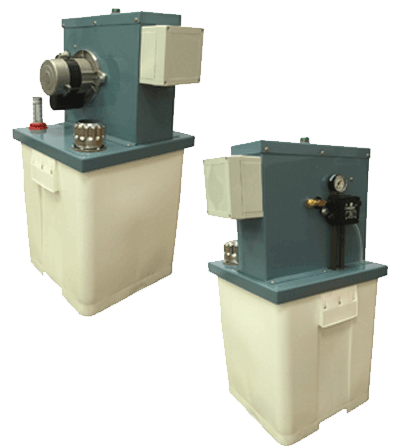

PAC’s Central Oil Mist Lubrication Systems for PSA trim and matrix removal prevent costly clogs

If your air-conveyed trim or label matrix removal system is dealing with pressure sensitive adhesive (PSA) materials, keeping your trim from sticking to the ductwork is a top priority. If just one piece of stray PSA trim sticks the inside of the duct, other PSA pieces will adhere to it, starting a snowball effect that can grind your production to a costly halt.

Precision AirConvey offers a two-pronged approach to efficiently handle trim and label matrix removal for PSA waste using a proprietary non-stick coating on selected ductwork and injecting a fine mineral oil mist into the process at the infeeds.

Companies that have multiple presses handling PSA trim and matrix waste can choose to use individual oil mist systems at each press or opt for a Central Oil Mist Lubrication System that supplies them all from a single container.

In some cases — such as small shops with only two or three presses — individual systems are the way to go, but more often than not, PAC’s newly designed Central Oil Mist Lubrication Systems will save companies substantial money and space.

The most obvious way central oil mist systems save companies money is through the purchase and installation of one piece of equipment rather than several. However, PAC’s central systems offer other, less obvious, cost-saving benefits as well.

1. Less labor is needed to maintain the systems. Instead of filling several smaller tanks with oil and then coming back to each periodically to check their oil levels, operators with a central system only need to fill one larger tank weekly, instead of daily. From this tank, lines pressurized to 70 psi deliver food-grade mineral oil to each press. Qualified personnel can customize oil distribution at each press to accommodate press speed and material. This affords companies the same flexibility they’d have if they had individual systems, but saves personnel the hassle of tending each. This customization also keeps companies from using more oil than they need to. The system will not shut down without first giving ample notification that oil is needed.

2. Costly clogs are avoided automatically. Precision AirConvey’s Central Oil Mist Lubrication System has a low-oil alarm that warns operators that the tank needs filling. In addition, there’s a failsafe built in: the control panel is interlocked with the overall control panel for the trim and label matrix removal system. If, for whatever reason, the oil runs out before an operator can refill it, the oiler control panel will shut down the entire trim and label matrix system in a controlled fashion rather than letting it run without oil, ensuring that expensive clogs never jam up your ductwork.

Precision AirConvey’s Central Oil Mist Lubrication System features one 55-gallon tank, which can be installed at a convenient location, apart from the production environment. Individual systems feature 13-gallon tanks located at each press. If pressroom floor space is at a premium in your multi-press shop, a central oil system is the best choice.